Deals of The Day

LHT Super Durabo Max Cut

1. Cutting Edge with Diamond Segments

2. Blade Core Materials

3. Blade Types

4. Cooling Mechanisms

5. Sizes and Compatibility

6. Cutting Efficiency

7. Durability

8. Versatility

9. Slot Designs

10. Speed and Feed Rate

Applications

LHT Supreme Red

1. Cutting Edge with Diamond Segments

2. Blade Core Materials

3. Blade Types

4. Cooling Mechanisms

5. Sizes and Compatibility

6. Cutting Efficiency

7. Durability

8. Versatility

9. Slot Designs

10. Speed and Feed Rate

Applications

LHT Hot Press Blue

LHT Silver

1. Cutting Edge with Diamond Segments

2. Blade Core Materials

3. Blade Types

4. Cooling Mechanisms

5. Sizes and Compatibility

6. Cutting Efficiency

7. Durability

8. Versatility

9. Slot Designs

10. Speed and Feed Rate

Applications

LHT Pro Max

1. Cutting Edge with Diamond Segments

2. Blade Core Materials

3. Blade Types

4. Cooling Mechanisms

5. Sizes and Compatibility

6. Cutting Efficiency

7. Durability

8. Versatility

9. Slot Designs

10. Speed and Feed Rate

Applications

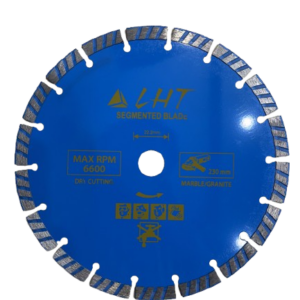

LHT Prism Segemented Blade

1. Cutting Edge with Diamond Segments

2. Blade Core Materials

3. Blade Types

4. Cooling Mechanisms

5. Sizes and Compatibility

6. Cutting Efficiency

7. Durability

8. Versatility

9. Slot Designs

10. Speed and Feed Rate

Applications

LHT Hot Press Red

LHT Hot Press Pro Max

LHT Extra

1. Cutting Edge with Diamond Segments

2. Blade Core Materials

3. Blade Types

4. Cooling Mechanisms

5. Sizes and Compatibility

6. Cutting Efficiency

7. Durability

8. Versatility

9. Slot Designs

10. Speed and Feed Rate

Applications

LHT Super Durabo Turbo

Product Description:

Achieve precision and smooth cuts with our Premium Diamond Marble Cutting Blade, specifically engineered for cutting marble and other natural stones. Designed with high-grade industrial diamonds, this blade ensures superior sharpness, durability, and efficiency in every cut.

Whether you’re a professional contractor or a DIY enthusiast, this blade delivers clean, chip-free edges while reducing heat buildup and vibration. Ideal for use with angle grinders, tile saws, and circular saws, it guarantees maximum performance in both wet and dry cutting applications.

LHT Steel Cutting Disc Green

Product Description:

Take your cutting tasks to the next level with the Steel Cutting Disc Green—engineered for precision, durability, and high performance. Whether you’re working on construction sites, in workshops, or handling DIY projects, this cutting disc delivers clean, accurate cuts through steel and other metals with ease.

LHT Steel Cutting Disc Red

Product Description:

Take your cutting tasks to the next level with the Steel Cutting Disc Red—engineered for precision, durability, and high performance. Whether you’re working on construction sites, in workshops, or handling DIY projects, this cutting disc delivers clean, accurate cuts through steel and other metals with ease.

Popular Categories this Week

-

Blade, Diamond Saw Blades

LHT Super Durabo Max Cut

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-2/25

SKU: LHT-D-2/25 -

Blade, Diamond Saw Blades

LHT Supreme Red

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-1/25 -

Blade, Tile Cutting Blades

LHT Hot Press Blue

- Features of Blue Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

- High-Performance Cutting: Engineered for precise and clean cuts on tiles, ceramics, and other hard materials.

- Super Thin Turbo Design: Ensures faster cutting speeds with minimal resistance.

- Sharp Diamond Blade: Provides enhanced sharpness for effortless cutting with reduced effort.

- No Chipping Technology: Delivers smooth, chip-free edges, ideal for professional results.

- Laser Cutting Accuracy: Equipped with advanced laser technology for precision and durability.

- Durable Construction: Designed for extended use without compromising performance.

- Versatile Application: Suitable for both dry and wet cutting tasks.

- High Heat Resistance: Maintains performance under high temperatures during prolonged usage.

- Universal Compatibility: Compatible with a wide range of tile cutting machines and angle grinders.

- Enhanced Safety Features: Minimizes vibrations and ensures stability during operation.

SKU: LHT-D-3/25-1 - Features of Blue Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

-

Blade, Diamond Saw Blades

LHT Silver

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

-

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-3/25-1-1 -

Blade, Diamond Saw Blades

LHT Pro Max

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-5/25-1 -

Blade, Diamond Saw Blades

LHT Prism Segemented Blade

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

-

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-6/25-1 -

Blade, Tile Cutting Blades

LHT Hot Press Red

- Features of Red Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

- High-Performance Cutting: Engineered for precise and clean cuts on tiles, ceramics, and other hard materials.

- Super Thin Turbo Design: Ensures faster cutting speeds with minimal resistance.

- Sharp Diamond Blade: Provides enhanced sharpness for effortless cutting with reduced effort.

- No Chipping Technology: Delivers smooth, chip-free edges, ideal for professional results.

- Laser Cutting Accuracy: Equipped with advanced laser technology for precision and durability.

- Durable Construction: Designed for extended use without compromising performance.

- Versatile Application: Suitable for both dry and wet cutting tasks.

- High Heat Resistance: Maintains performance under high temperatures during prolonged usage.

- Universal Compatibility: Compatible with a wide range of tile cutting machines and angle grinders.

- Enhanced Safety Features: Minimizes vibrations and ensures stability during operation.

SKU: LHT-D-3/25-1-2 - Features of Red Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

-

Blade, Tile Cutting Blades

LHT Hot Press Pro Max

- Features of Green Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

- High-Performance Cutting: Engineered for precise and clean cuts on tiles, ceramics, and other hard materials.

- Super Thin Turbo Design: Ensures faster cutting speeds with minimal resistance.

- Sharp Diamond Blade: Provides enhanced sharpness for effortless cutting with reduced effort.

- No Chipping Technology: Delivers smooth, chip-free edges, ideal for professional results.

- Laser Cutting Accuracy: Equipped with advanced laser technology for precision and durability.

- Durable Construction: Designed for extended use without compromising performance.

- Versatile Application: Suitable for both dry and wet cutting tasks.

- High Heat Resistance: Maintains performance under high temperatures during prolonged usage.

- Universal Compatibility: Compatible with a wide range of tile cutting machines and angle grinders.

- Enhanced Safety Features: Minimizes vibrations and ensures stability during operation.

SKU: LHT-D-3/25-1-2-1 - Features of Green Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

Headphones

-

Blade, Diamond Saw Blades

LHT Super Durabo Max Cut

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-2/25

SKU: LHT-D-2/25 -

Blade, Diamond Saw Blades

LHT Supreme Red

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-1/25 -

Blade, Tile Cutting Blades

LHT Hot Press Blue

- Features of Blue Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

- High-Performance Cutting: Engineered for precise and clean cuts on tiles, ceramics, and other hard materials.

- Super Thin Turbo Design: Ensures faster cutting speeds with minimal resistance.

- Sharp Diamond Blade: Provides enhanced sharpness for effortless cutting with reduced effort.

- No Chipping Technology: Delivers smooth, chip-free edges, ideal for professional results.

- Laser Cutting Accuracy: Equipped with advanced laser technology for precision and durability.

- Durable Construction: Designed for extended use without compromising performance.

- Versatile Application: Suitable for both dry and wet cutting tasks.

- High Heat Resistance: Maintains performance under high temperatures during prolonged usage.

- Universal Compatibility: Compatible with a wide range of tile cutting machines and angle grinders.

- Enhanced Safety Features: Minimizes vibrations and ensures stability during operation.

SKU: LHT-D-3/25-1 - Features of Blue Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

-

Blade, Diamond Saw Blades

LHT Silver

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

-

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-3/25-1-1 -

Blade, Diamond Saw Blades

LHT Pro Max

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-5/25-1 -

Blade, Diamond Saw Blades

LHT Prism Segemented Blade

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

-

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-6/25-1

Smartphones & Tablets

Recommendation For You

View All Recommendations-

Blade, Diamond Saw Blades

LHT Super Durabo Max Cut

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-2/25

SKU: LHT-D-2/25 -

Blade, Diamond Saw Blades

LHT Supreme Red

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-1/25 -

Blade, Tile Cutting Blades

LHT Hot Press Blue

- Features of Blue Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

- High-Performance Cutting: Engineered for precise and clean cuts on tiles, ceramics, and other hard materials.

- Super Thin Turbo Design: Ensures faster cutting speeds with minimal resistance.

- Sharp Diamond Blade: Provides enhanced sharpness for effortless cutting with reduced effort.

- No Chipping Technology: Delivers smooth, chip-free edges, ideal for professional results.

- Laser Cutting Accuracy: Equipped with advanced laser technology for precision and durability.

- Durable Construction: Designed for extended use without compromising performance.

- Versatile Application: Suitable for both dry and wet cutting tasks.

- High Heat Resistance: Maintains performance under high temperatures during prolonged usage.

- Universal Compatibility: Compatible with a wide range of tile cutting machines and angle grinders.

- Enhanced Safety Features: Minimizes vibrations and ensures stability during operation.

SKU: LHT-D-3/25-1 - Features of Blue Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

-

Blade, Diamond Saw Blades

LHT Silver

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

-

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-3/25-1-1 -

Blade, Diamond Saw Blades

LHT Pro Max

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-5/25-1 -

Blade, Diamond Saw Blades

LHT Prism Segemented Blade

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

-

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-6/25-1 -

Blade, Tile Cutting Blades

LHT Hot Press Red

- Features of Red Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

- High-Performance Cutting: Engineered for precise and clean cuts on tiles, ceramics, and other hard materials.

- Super Thin Turbo Design: Ensures faster cutting speeds with minimal resistance.

- Sharp Diamond Blade: Provides enhanced sharpness for effortless cutting with reduced effort.

- No Chipping Technology: Delivers smooth, chip-free edges, ideal for professional results.

- Laser Cutting Accuracy: Equipped with advanced laser technology for precision and durability.

- Durable Construction: Designed for extended use without compromising performance.

- Versatile Application: Suitable for both dry and wet cutting tasks.

- High Heat Resistance: Maintains performance under high temperatures during prolonged usage.

- Universal Compatibility: Compatible with a wide range of tile cutting machines and angle grinders.

- Enhanced Safety Features: Minimizes vibrations and ensures stability during operation.

SKU: LHT-D-3/25-1-2 - Features of Red Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

-

Blade, Tile Cutting Blades

LHT Hot Press Pro Max

- Features of Green Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

- High-Performance Cutting: Engineered for precise and clean cuts on tiles, ceramics, and other hard materials.

- Super Thin Turbo Design: Ensures faster cutting speeds with minimal resistance.

- Sharp Diamond Blade: Provides enhanced sharpness for effortless cutting with reduced effort.

- No Chipping Technology: Delivers smooth, chip-free edges, ideal for professional results.

- Laser Cutting Accuracy: Equipped with advanced laser technology for precision and durability.

- Durable Construction: Designed for extended use without compromising performance.

- Versatile Application: Suitable for both dry and wet cutting tasks.

- High Heat Resistance: Maintains performance under high temperatures during prolonged usage.

- Universal Compatibility: Compatible with a wide range of tile cutting machines and angle grinders.

- Enhanced Safety Features: Minimizes vibrations and ensures stability during operation.

SKU: LHT-D-3/25-1-2-1 - Features of Green Tile Cutting Disk with Sharp Blade Super Thin Turbo (Turbo Diamond Blade):

-

Blade, Diamond Saw Blades

LHT Extra

1. Cutting Edge with Diamond Segments

- Diamond Composition: Made of synthetic or natural diamond particles bonded with metal or resin.

- Segments: These are strategically placed for efficient cutting, often separated by slots to reduce heat and allow debris removal.

2. Blade Core Materials

- Typically made of high-strength steel or other alloys to ensure durability and stability during high-speed operations.

3. Blade Types

- Continuous Rim: Smooth cutting for delicate materials like tiles and ceramics.

- Segmented Blade: Fast cutting of hard materials like concrete and asphalt, with segmented teeth for cooling.

- Turbo Blade: Combines smoothness and speed, suitable for stone and masonry.

4. Cooling Mechanisms

- Water Cooling: Many blades require water to reduce friction, heat, and dust.

- Dry Cutting: Designed with slots or special bonds to handle heat without water.

5. Sizes and Compatibility

- Available in a range of diameters to fit various cutting tools, from handheld saws to large industrial machines.

6. Cutting Efficiency

- Capable of precise, fast, and clean cuts with minimal chipping on hard materials.

7. Durability

- High resistance to wear and tear due to the hardness of diamond particles.

8. Versatility

- Suitable for a variety of materials, including stone, concrete, asphalt, tiles, and glass.

9. Slot Designs

- Gullets: Reduce friction and improve airflow.

- Laser-Cut Slots: Offer noise reduction and heat dissipation.

10. Speed and Feed Rate

- Designed for high-speed applications, balancing feed rate and cutting depth efficiently.

Applications

- Construction: Cutting concrete, asphalt, and bricks.

- Masonry: Shaping stones and tiles.

- Industrial: Precision cutting of ceramics and glass.

SKU: LHT-D-2/25-1 -

Blade, Marble Cutting Blades

LHT Super Durabo Turbo

Product Description:

Achieve precision and smooth cuts with our Premium Diamond Marble Cutting Blade, specifically engineered for cutting marble and other natural stones. Designed with high-grade industrial diamonds, this blade ensures superior sharpness, durability, and efficiency in every cut.

Whether you’re a professional contractor or a DIY enthusiast, this blade delivers clean, chip-free edges while reducing heat buildup and vibration. Ideal for use with angle grinders, tile saws, and circular saws, it guarantees maximum performance in both wet and dry cutting applications.

SKU: LHT-D-2/25-2 -

Disc, Steel Cutting Disc

LHT Steel Cutting Disc Green

Product Description:

Take your cutting tasks to the next level with the Steel Cutting Disc Green—engineered for precision, durability, and high performance. Whether you’re working on construction sites, in workshops, or handling DIY projects, this cutting disc delivers clean, accurate cuts through steel and other metals with ease.

SKU: LHT-D-2/25-2-1 -

Disc, Steel Cutting Disc

LHT Steel Cutting Disc Red

Product Description:

Take your cutting tasks to the next level with the Steel Cutting Disc Red—engineered for precision, durability, and high performance. Whether you’re working on construction sites, in workshops, or handling DIY projects, this cutting disc delivers clean, accurate cuts through steel and other metals with ease.

SKU: LHT-D-2/25-2-1